Views: 0 Author: Site Editor Publish Time: 2025-11-06 Origin: Site

In the automotive industry, the packaging of automotive parts is crucial for ensuring the safe delivery of products, enhancing brand image and meeting regulatory standards. This article will explore the best solutions for automotive parts packaging, providing valuable insights for enterprises aiming to optimize their packaging strategies. From recognizing the importance of correct packaging, choosing the right materials and implementing effective strategies, we delve into the nuances of packaging in the automotive industry. Whether you are an experienced business owner or a newcomer in this field, this comprehensive guide can provide you with effective knowledge for navigating packaging and transportation regulations. Introduced by TOYOE Packaging System, your trusted expert in packaging design services.

In the automotive industry, the value of proper packaging is supreme. It ensures that auto parts arrive at the destination in their original condition, thereby enhancing customer satisfaction and fostering trust in the brand's reliability. Effective packaging serves a dual purpose - it not only protects goods from potential damage during transportation, but also helps shape your company's image. Given the wide variety of automotive parts, each with its unique characteristics and susceptibility to damage, determining the correct packaging solution can be daunting. This article aims to guide you in using the best strategies and materials, simplify processes, and save valuable business resources at the same time. In addition, adhering to continuously improved packaging regulations will help enhance your company's dedication to quality and legal compliance.

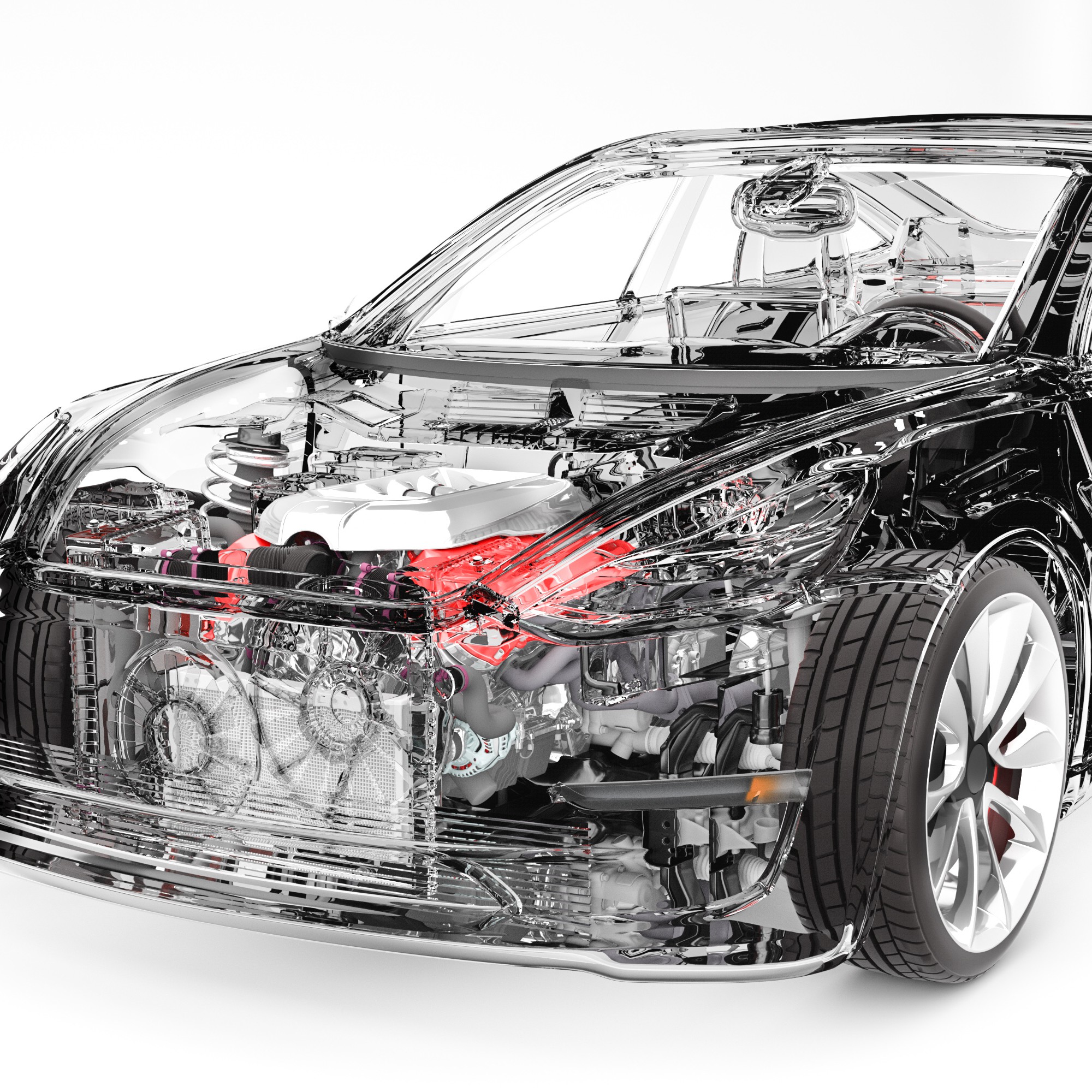

During transportation and storage, packaging serves as a crucial barrier for vehicle components. Every component of a vehicle, whether it is the engine, transmission, body parts or electronic devices, has unique characteristics and vulnerabilities.

This requires specific packaging methods to prevent damage caused by impact, vibration, moisture, dust or improper operation. High-quality packaging materials can absorb shock and vibration during transportation, thereby protecting components from potential damage. For instance, materials such as corrugated boxes, foam or bubble packaging can provide effective cushioning for fragile parts.

In addition, protective packaging serves as a barrier against environmental factors. Moisture-proof packaging can prevent metal parts from corroding due to humidity exposure, while dust-proof packaging ensures that electronic products and other sensitive components remain clean during storage and transportation.

Proper packaging can also reduce the risk of sharp or heavy components causing injury to the people handling them. Customized packaging provides a safe location for each vehicle component, minimizing the chances of confusion and damage. Essentially, effective packaging helps protect vehicle components from potential hazards during transportation and storage, ensuring their integrity from the warehouse to the customer.

Therefore, investing in a strong and high-quality packaging protocol is an indispensable aspect of the automotive parts business.

The packaging of auto parts is a tangible representation of a brand and is usually the first physical point of contact for customers. A well-crafted package can leave a lasting impression and establish a strong connection with your customers. It is not merely a protective shell for your product, but also an effective marketing tool that can significantly enhance your brand image.

Remember, the packaging of a product often plays a crucial role in its sales. Incorporating elements of brand identity, such as trademarks or slogans, into packaging design can enhance brand recognition. This immediate identification of the source of packaging Bridges the gap between the physical product and its creator. Furthermore, the quality of packaging is a direct reflection of brand value. The sturdy and professionally designed packaging indicates a commitment to providing first-class products.

At the same time, using eco-friendly materials can emphasize your brand's commitment to environmental sustainability and enhance your image of social responsibility. Unique packaging can also help your brand stand out in the highly competitive market. This may involve the use of unconventional materials, creative designs, or providing a unique unboxing experience. This uniqueness can create unforgettable experiences for your customers and encourage brand loyalty. In addition, easy-to-open, clearly labeled and well-organized packaging enhances user convenience and enriches the interaction between customers and your brand.

This positive experience can enhance customer satisfaction and further improve your brand image. Essentially, packaging is not merely the practical need to protect automotive parts; This is an important opportunity to build your brand. By integrating marketing strategies with packaging design, enterprises can establish a strong and positive brand image that complements their high-quality products.

When it comes to packaging vehicle parts, a universal solution is non-existent. Each part, with its unique characteristics and requirements, demands a specific type of packaging material for optimal protection. Thus, the selection of appropriate packaging materials is a critical aspect that hinges on the physical properties of the part in question.

For instance, delicate components often necessitate robust, shock-absorbing materials like corrugated cardboard or molded polystyrene. Parts that are susceptible to moisture and dust may benefit from the use of sealed plastic bags or wraps.

Heavy-duty components such as engines or transmissions may require wooden crates or pallets for their strength and durability. On the other hand, antistatic bags or bubble wrap can shield sensitive electronic parts from electrostatic discharge effectively.

Moreover, the chosen packaging material should also reflect your company's environmental responsibilities. Prioritizing recyclable and biodegradable

The choice of packaging materials is largely influenced by the specific characteristics and requirements of the vehicle parts. Here’s a look at the packaging needs of different types of vehicle components:

Body Components: Large parts such as bumpers and body panels demand sturdy protection. Molded plastic or foam can provide excellent defense against scratches and dents. For added security during transit, these can be housed in double-wall corrugated cardboard boxes.

Engine Parts: Given their weight and robust nature, engine parts necessitate strong packaging. Wooden crates or pallets fortified with metal brackets are often the go-to choice. Their strength and durability make them ideal for heavy items like engine blocks or transmissions.

Battery and Electronic Components: These items are sensitive to electrostatic discharge and require special packaging. Antistatic bags, bubble wrap, or foam are ideal as they can dissipate electric charges, ensuring the safety of these parts.

Small and Delicate Parts: Smaller items such as valves and sensors can be securely packaged using poly bags, small boxes, or compartmentalized containers. For added shock and vibration protection, consider using bubble wrap or foam inserts.

Fluid-Filled Components: Parts that contain fluid, like brake fluid reservoirs, need leak-proof packaging. Strong, sealed plastic containers are a suitable choice for these components.

Windshield and Glass: These fragile components require protective packaging to prevent cracking and breaking. Corrugated boxes lined with foam or bubble wrap provide excellent cushioning.

The key takeaway here is to match the packaging material to the part’s needs, considering its weight, size, and sensitivity. This approach will help protect your products, reduce returns, and boost customer satisfaction.

A well-executed packaging strategy is as crucial as choosing the right materials. It enhances the safety of vehicle parts during transit, optimizes storage, improves handling, and cuts costs.

The first step in devising a sound packaging strategy is to thoroughly assess the product – its weight, dimensions, fragility, and value. Next, consider the logistics – how will the product be stacked, moved, stored, and transported?

Packages that are correctly sized minimize the risk of damage during transit, reduce waste, and maximize transport efficiency. The product should fit comfortably within the packaging without being forced. Remember, unused space equates to wasted resources.

Consideration should also be given to the shape and size of the package for efficient warehouse storage. Regular-shaped, stackable packages make better use of space and simplify logistics operations, thereby reducing labor and storage costs.

A comprehensive vehicle parts packaging strategy should also include containment strategies to ensure all related components are packaged together. This not only offers protection but also enhances the unpacking experience for the customer.

Committing to sustainable packaging by using recyclable or reusable materials not only benefits the environment but also underscores your brand's commitment to sustainable practices, a factor that is increasingly important to consumers.

Finally, it’s important to continually assess performance and seek opportunities for improvement. Regular monitoring and adjustments based on factors such as transport conditions, customer feedback, and cost-effectiveness will ensure your packaging strategy remains effective and efficient over time.

In the following sections, we’ll explore specific strategies for optimizing storage and reducing costs, and ensuring product safety.

In the realm of vehicle parts distribution, smart packaging is a game-changer. It's an innovative approach that focuses on maximizing storage efficiency and minimizing costs associated with packaging and shipping. Here’s how you can leverage smart packaging to your advantage:

Customized Dimensions: Tailoring package sizes to the exact dimensions of your vehicle parts can eliminate unnecessary volume and weight. This not only reduces shipping costs but also minimizes potential damage from parts shifting within oversized packages.

Stackable Solutions: Opt for boxes or pallets designed for efficient stacking. This can significantly reduce storage space requirements in your warehouse and transport vehicles, while also simplifying and enhancing safety during handling.

Kit and Multipack Packaging: When shipping multiple identical or related parts, consider using multipack or kit packaging. This approach can save considerable space compared to individual packaging and also simplifies the unpacking process for your customers.

Light Yet Durable Materials: While robust packaging materials are crucial for protecting vehicle parts, their weight can inflate shipping costs. Materials like corrugated cardboard or certain plastics offer a balance of strength and lightness.

Consolidation: Consolidation involves packing several smaller boxes into a larger one, significantly reducing the number of individual packages to be handled. This can lead to substantial cost and labor savings.

Reusable Packaging: If your business frequently ships to the same location, reusable packaging can yield significant cost savings over time.

In a nutshell, smart packaging is all about maximizing efficiency and minimizing costs at every stage of your packaging process. By adopting these strategies, you can reduce storage and shipping costs, ultimately boosting your bottom line.

In the automotive industry, ensuring the safety of vehicle parts during transit is paramount. While selecting the right packaging material is the first step, there are additional measures you can take to further safeguard your products.

Adequate Padding: No matter how sturdy your outer packaging is, adding sufficient padding to absorb shocks or vibrations during transport is essential. Materials like bubble wrap, packing peanuts, or foam inserts are ideal for this purpose.

Secure Sealing: All packages should be securely sealed with a strong adhesive tape, with all closures and seams reinforced for added protection.

Use of Damage Indicators: Damage indicators such as shock and tilt indicators can be invaluable. These devices can detect rough handling during transit, holding freight carriers accountable for any damage.

Moisture Protection: If your parts are susceptible to water or moisture damage, use water-resistant packaging materials. Sealed plastic wrap can provide an additional layer of protection.

Clear Handling Instructions: Simple, visible handling instructions like 'Fragile', 'This Side Up', or 'Keep Dry' can greatly assist in the safe handling and transport of your vehicle parts.

Secure Fastening: For heavy or unusually shaped parts, secure them to the pallet or crate using straps or shrink wrap to prevent movement during transit.

By implementing these strategies, you can significantly enhance the safety of your vehicle parts during shipping, reducing the likelihood of damages and returns. Secure packaging is more than just a cost – it’s an investment in customer trust and product integrity.

The automotive industry places a high premium on safety, extending beyond vehicle operation to the packaging and transportation of vehicle parts. Compliance with packaging regulations is not only a legal necessity but also a measure to ensure the safe and secure transit of automotive components.

The specific regulations you need to adhere to will vary, depending on the type of parts being shipped, the destination, and the chosen mode of transport. For example, hazardous items such as batteries and brake fluids have unique packaging requirements that must be strictly followed.

Environmental considerations also factor into these regulations. Many regions enforce stringent rules regarding waste management and the use of recyclable or minimal packaging materials.

It's important to note that regulations are frequently updated. Staying abreast of these changes is crucial to avoid penalties, shipment delays, and potential damage to your business reputation.

As we move into the final section of this article, we'll provide some key insights to help you understand and navigate the complex landscape of packaging and shipping regulations. These tips are vital to your packaging strategy and can help you avoid costly penalties and disruptions.