Views: 0 Author: Site Editor Publish Time: 2025-12-29 Origin: Site

When selecting the right size bulk container, it’s crucial to look beyond just volume. Usable capacity, footprint, and how you move or access the product are key factors. Choosing the right size reduces handling costs, minimizes wasted space, and prevents product loss.

In this guide, you’ll learn how to effectively choose the best size bulk plastic container for your needs. We’ll provide a repeatable method to optimize your operations and ensure compliance with industry standards.

The size of your bulk container will vary depending on whether you're using it for storage, work-in-progress (WIP) staging, or shipping. Each use case will influence the capacity needs and design considerations. Below is a breakdown of the different use cases and their container size requirements:

Use Case | Key Considerations | Container Size |

Storage | Requires long-term holding with potential for product expansion. | Larger containers with extra headspace for expansion and long-term storage. |

WIP Staging | Designed for easy handling and movement within the production line. | Smaller, more manageable sizes for quick access and frequent handling. |

Shipping | Optimized for transporting goods efficiently, adhering to shipping limits. | Size tailored for transport, ensuring maximum efficiency without exceeding shipping constraints. |

By aligning the container size with the specific use case, you can ensure that the container meets operational needs effectively and cost-efficiently.

You need to calculate how much product you need per container. For example, based on your production schedule or shipping requirements, decide how many days or hours of product you’ll store or transport in each container. This step prevents the issue of chronic oversizing or undersizing.

When selecting the right size bulk container, it's important to consider how different products behave in terms of weight and volume. Liquids, powders, and solids all have distinct properties that affect how much can be stored or shipped. Below is a breakdown of how these properties impact the required container size:

Product Type | Key Considerations | Container Size Impact |

Liquids | Temperature fluctuations can cause volume changes due to expansion. | Ensure extra space for expansion and foam or slosh. |

Powders | Settling and compaction can reduce the usable volume. | Account for settling and possible loss of volume. |

Solids | Can vary in size and weight, often influenced by shape. | Consider irregular packing and void spaces between particles. |

When it comes to liquids, always allow extra space in the container to accommodate slosh, foam, and temperature expansion. Similarly, ensure the container is not filled to its maximum capacity to avoid spills, bulging, or compromised lids during transportation or handling.

Be sure your handling equipment can accommodate the weight of a fully-loaded container. A larger container may hold more, but if your team or equipment can't safely move it, it could lead to safety issues or damage to both the container and product.

Once you’ve narrowed down the size, run a quick test with one container that is slightly smaller and one that is larger than your target size. This allows you to see how they fit into your workflow and whether there are any issues with movement, stacking, or storage.

To make the decision easier, start by considering standard size families. For example:

● Tote tanks/IBC containers can hold up to 6,000 liters.

● Steel drums typically hold 208 liters.

These benchmarks help you quickly eliminate sizes that are too small or too large for your needs.

Different operations require different container sizes:

● Smaller containers are ideal for daily-use in labs or small batch production.

● Larger containers are more suited for bulk transfers, often used for shipments or large-scale manufacturing processes.

Always ask for the internal dimensions of the container, not just the external volume. The listed volume might include unusable space (e.g., container walls, closures). Similarly, confirm whether accessories like liners, valves, or outlets will reduce usable capacity.

Before selecting a size, ensure it will fit your existing infrastructure. If the container is too large for your pallets, racks, aisles, or doorways, it will create a bottleneck and disrupt your workflow.

Proper stacking can maximize storage space by up to 36%. However, it’s critical to ensure the container's design supports safe stacking, and that you don't exceed weight limits or cause instability.

Choose a container that uses the space efficiently. Oversized containers could lead to paying for unused volume, especially in shipping. Instead, select a container that maximizes the usable volume without wasting space or causing instability during transit.

Depending on the type of handling equipment available, the size of the container may need to be adjusted. Ensure that forklift pockets, pallet jack compatibility, and turning radii are accounted for to avoid equipment breakdowns or inefficient handling.

How you access the product in the container will also influence the size:

● Picking (manual or automated) requires access doors or drop fronts.

● Dumping or dispensing involves the need for valves or a secure outlet to control product flow.

Automation in warehouses can be hindered by containers that vary too much in size. Standardizing container sizes across your operation will reduce the need for adjustments, improving efficiency and reducing downtime.

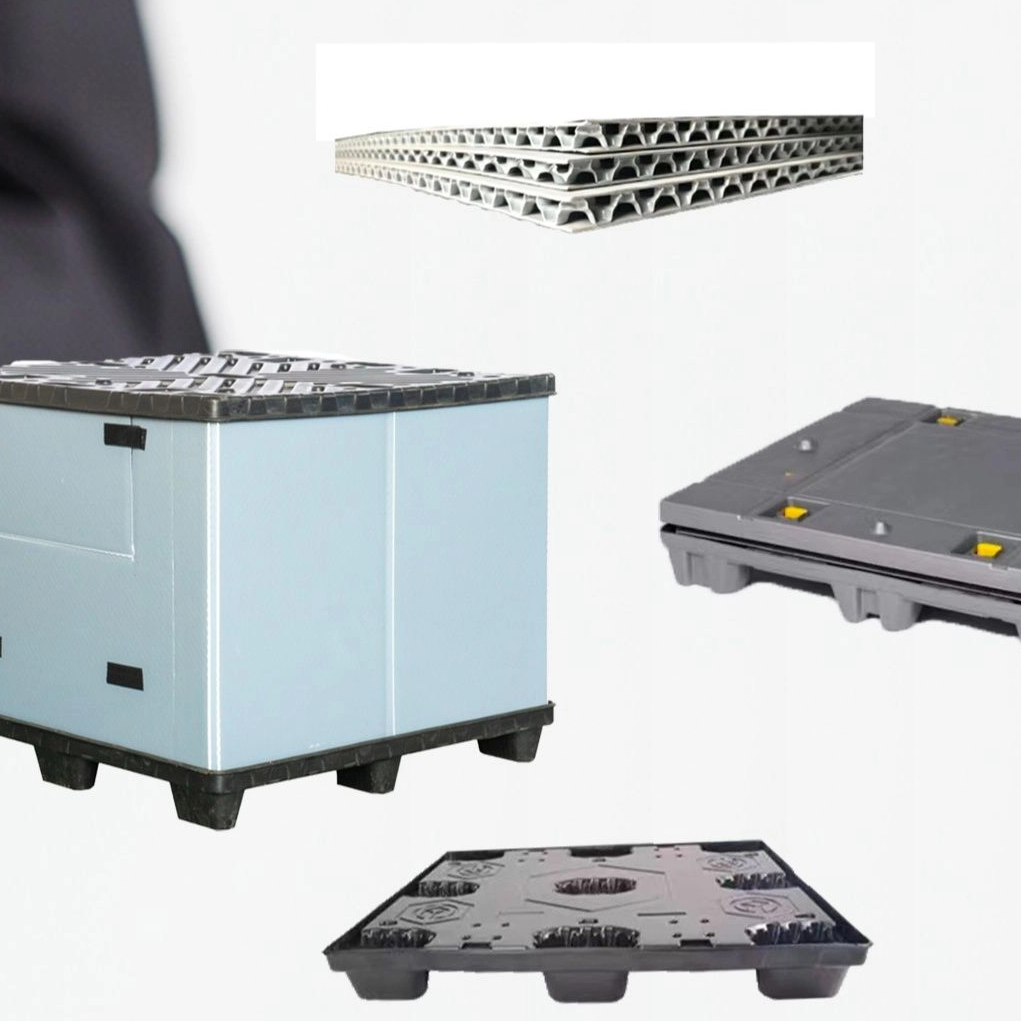

Bulk plastic containers are lightweight, durable, and easy to clean. These qualities make them ideal for many industries, including food, chemicals, and manufacturing. Their versatility and reusability make them the go-to choice for operations that require frequent handling.

In some cases, other materials may be more suitable than bulk plastic containers, depending on the product and handling requirements. Here's a breakdown of when to consider alternatives such as metal containers, fiberboard, or bulk bags:

Container Material | Best Use Cases |

Metal Containers | Ideal for heavy, high-durability needs. |

Fiberboard Containers | Best for dry, non-perishable products. |

Bulk Bags (FIBCs) | Efficient for bulk transport of dry goods but not ideal for stacking. |

When selecting a bulk plastic container, consider design features that contribute to safety and efficiency:

● Lids and covers to prevent contamination or spills.

● Interlocking stacks to optimize storage.

● Forklift pockets for safe handling.

● Purpose-specific access points for dispensing or picking.

Certain industries, like food, chemicals, and pharmaceuticals, are governed by strict regulations regarding material safety, cleanability, and product integrity. Be sure the container size meets these certifications and requirements before proceeding.

Local regulations, like the EU Packaging and Packaging Waste Regulation, may mandate certain standards for recyclable materials or eco-friendly packaging. These regulations may restrict your choice of size, material, or type of container.

Larger containers increase the risk of product theft, damage, or loss, especially when dealing with high-value goods. Consider integrating tamper-evident features or tracking systems to secure larger loads.

When evaluating bulk containers, the total cost of ownership (TCO) is more important than the unit price. Consider factors like handling, damage rates, storage space, transport cube, and product loss.

The environmental impact of packaging can make up up to ~10% of a product’s carbon footprint. Choosing the right size bulk plastic container reduces unnecessary material use and shipping air, helping meet sustainability goals.

Reusable bulk containers significantly reduce waste and overall costs over time. By selecting durable containers that are compatible with your handling systems, you’ll reduce the need for frequent replacements and minimize long-term waste.

Choosing the right size bulk container is crucial for optimizing operations. It involves balancing product needs, handling requirements, and compliance. The process should include assessing use cases, required volume, headspace, and stacking, along with handling and compliance checks. Regularly reviewing your container fleet and standardizing a few sizes will improve efficiency and reduce costs.

At Zhangjiagang Fenghui Logistics Equipment Co., Ltd., our bulk plastic containers are designed to meet these needs. We provide reliable, durable solutions that enhance operational efficiency and reduce waste, offering excellent value for businesses in various industries.

A: Start by assessing your product's form, flow, and fragility. Then calculate the required volume, headspace, and handling needs. Finally, test a couple of container sizes before standardizing.

A: Bulk plastic containers are durable, lightweight, and easy to clean. They optimize storage, reduce handling costs, and improve efficiency across various industries, including food and manufacturing.

A: Calculate the product's exact working volume, including headspace for liquids or flow properties for solids. Testing a few sizes in your workflow can help avoid inefficiency.

A: Standardizing bulk plastic containers helps streamline operations, reduce downtime, and ensure consistency in handling, storage, and transportation.

A: Choose based on the product type, durability needs, and environmental factors. Bulk plastic containers are ideal for frequent handling, while metals may be better for heavy-duty applications.

A: Proper sizing ensures efficient use of space and reduces transport costs by minimizing wasted air and optimizing stackability in your facility.