Have you ever wondered what makes packaging materials so durable and versatile? One such material is High-Density Polyethylene (HDPE), which is widely used in industries around the world. HDPE boxes, made from this polymer, offer unmatched strength and adaptability for various applications.

In this article, we will explore what an HDPE box is, its key properties, advantages, and how it’s made. By the end, you’ll understand why HDPE boxes are essential in industries ranging from food storage to chemical packaging.

HDPE, or High-Density Polyethylene, is a type of thermoplastic polymer made from petroleum. This material is characterized by its high strength-to-density ratio, which makes it stronger, more durable, and more rigid than other types of polyethylene such as Low-Density Polyethylene (LDPE). HDPE is also known for its resistance to chemical corrosion, making it suitable for many applications that involve exposure to harsh chemicals, moisture, and environmental factors.

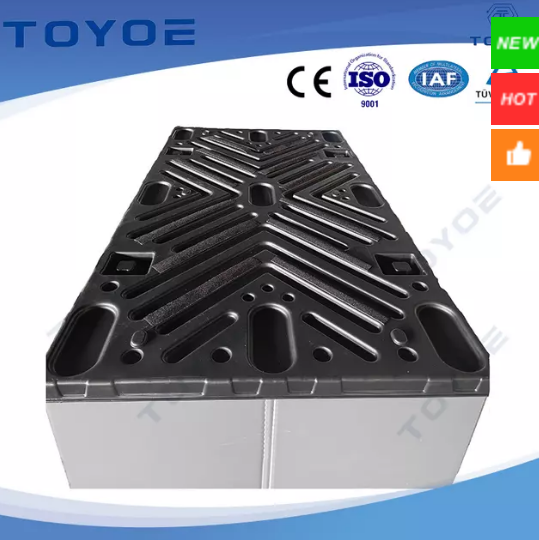

An HDPE box is a container made from High-Density Polyethylene, typically used for storage, transportation, and packaging. These boxes are known for their strength, resilience, and cost-effectiveness. They come in a variety of shapes and sizes, which makes them suitable for both domestic and industrial uses. The boxes can be used to store a wide range of products, from food and chemicals to industrial materials and personal items.

One of the most significant advantages of HDPE boxes is their exceptional durability. HDPE is highly resistant to impact, cracking, and wear. These qualities make HDPE boxes ideal for environments where the boxes will be exposed to heavy handling, rough transportation, or extreme weather conditions. HDPE boxes can withstand both high and low temperatures, maintaining their integrity even under harsh conditions.

Tip: Consider HDPE boxes for applications in industries where durability and impact resistance are a priority, such as construction or logistics.

HDPE is highly resistant to many chemicals, including acids, bases, and solvents. This makes HDPE boxes a preferred choice in industries that deal with chemicals, such as pharmaceuticals, agriculture, and manufacturing. The chemical resistance ensures that the boxes will not degrade or weaken when exposed to harsh substances, ensuring that the contents inside are safely stored without contamination.

Despite its strength, HDPE is a lightweight material, which makes it ideal for storage and transportation. This strength-to-density ratio means that HDPE boxes can hold heavy loads while remaining easy to handle and transport. The lightweight nature of these boxes reduces shipping costs, which is a significant advantage in commercial and industrial applications.

Property | Description |

Durability | Resistant to impact and physical stress |

Chemical Resistance | Resists a wide range of chemicals |

Lightweight | Easy to handle and transport |

Eco-Friendly | Recyclable and supports sustainability |

Strength | High strength-to-density ratio, suitable for heavy-duty use |

HDPE boxes are highly economical compared to other materials such as metal or glass. The manufacturing process for HDPE is relatively inexpensive, making it a cost-effective solution for businesses. In addition to the low production cost, HDPE boxes also help reduce operational costs by offering durability, reducing breakage rates, and lowering shipping and storage costs due to their light weight.

HDPE is one of the most widely recycled plastics, with a recycling code of “2” under the universal recycling symbol. This makes HDPE boxes a sustainable packaging solution, as they can be recycled and reused, reducing environmental waste. Using recycled HDPE, or rHDPE, is a great way for businesses to support the circular economy and meet their sustainability goals.

HDPE boxes are incredibly versatile. They can be used in a wide range of industries and applications. From food and beverage packaging to industrial storage, HDPE boxes are an ideal choice due to their strength, versatility, and recyclability. They can be customized in different shapes, sizes, and colors, which makes them suitable for a variety of storage and packaging needs.

HDPE boxes are commonly used for packaging and storage across various industries. In the food and beverage sector, HDPE boxes are used for packaging liquids like milk and juices. These boxes ensure that the contents are safely stored and transported without the risk of contamination. In the chemical industry, HDPE boxes are used to store and transport chemicals, detergents, and other industrial products, thanks to their chemical resistance.

In addition to packaging, HDPE boxes are used in many industrial applications. They serve as storage containers for raw materials, finished goods, and tools in manufacturing environments. HDPE is also used in the construction industry for materials such as pipes and insulation. The durability and strength of HDPE make it suitable for use in tough, industrial environments.

At the consumer level, HDPE boxes are often used for household storage. They are commonly found in garages, kitchens, and closets for organizing tools, toys, and personal items. These boxes are also used in retail to display and organize products on shelves. Their versatility makes them a popular choice for home and commercial storage solutions.

Industry | Common Use |

Food & Beverage | Storage for liquids like milk and juices |

Chemicals | Packaging for industrial and household chemicals |

Pharmaceuticals | Storage for medicines and medical supplies |

Agriculture | Containers for fertilizers and pesticides |

Retail | Storage and display for various products |

The production of HDPE boxes involves several steps, including molding and shaping the plastic into containers. The most common methods for manufacturing HDPE boxes are:

● Injection Molding: In this process, HDPE is melted and injected into molds under high pressure to form the desired shape of the box. This method is highly efficient for producing large quantities of uniform containers.

● Blow Molding: This process is used for producing hollow containers. The HDPE material is extruded into a tube, which is then inflated within a mold to form the shape of the box. Blow molding is commonly used for producing bottles and large containers.

HDPE boxes can be customized to suit specific requirements. They can be molded into various shapes, sizes, and colors, depending on the intended use. Custom features such as lids, handles, and dividers can also be added to improve functionality and ease of use.

HDPE and PET (Polyethylene Terephthalate) are both commonly used materials for packaging, but they differ in several ways. HDPE is opaque, durable, and more resistant to chemical exposure than PET, which is often used for products that require transparency, such as water bottles. HDPE is also more impact-resistant and has better strength for heavy-duty applications, making it a preferred choice for industrial use.

While both HDPE and polypropylene are strong, durable plastics, HDPE is more resistant to environmental stress and can withstand higher temperatures. Polypropylene, on the other hand, is more flexible and is often used in applications that require more flexibility, such as medical packaging. HDPE boxes are preferred in industries like chemicals and food packaging due to their superior rigidity and chemical resistance.

The demand for HDPE boxes is expected to grow as more industries move towards sustainable, recyclable packaging solutions. Innovations in HDPE manufacturing processes, such as the development of even stronger and more versatile materials, are likely to drive further adoption of HDPE boxes across various sectors. As sustainability becomes increasingly important to businesses and consumers, HDPE boxes will play a crucial role in reducing environmental impact and promoting eco-friendly practices.

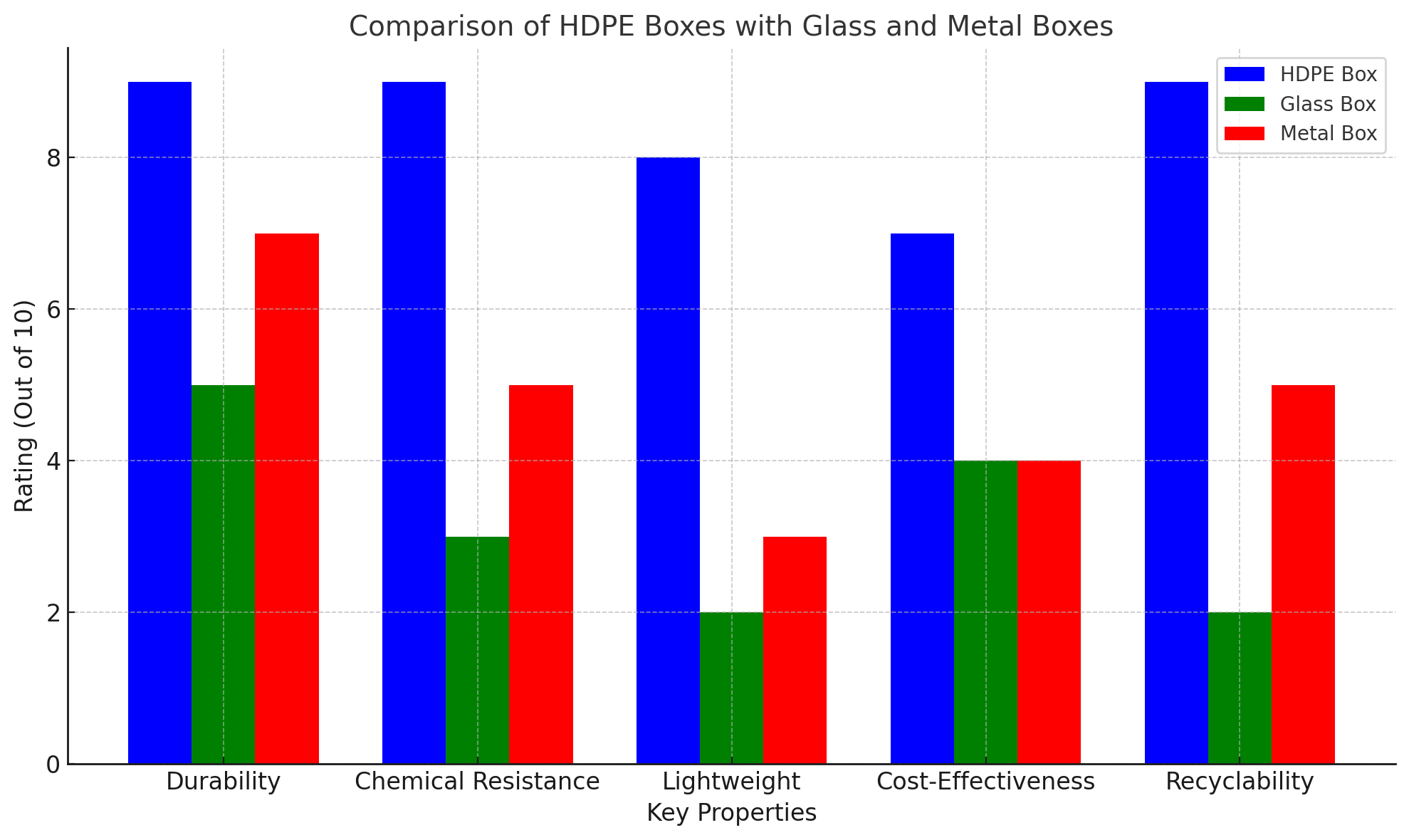

Property | HDPE Boxes | Glass Boxes | Metal Boxes |

Durability | High impact resistance | Fragile, prone to breaking | Strong, but heavier |

Chemical Resistance | Excellent | Low | Moderate |

Weight | Lightweight | Heavy | Heavy |

Cost | Cost-effective | Expensive | Expensive |

Recyclability | Highly recyclable | Difficult to recycle | Limited recyclability |

HDPE boxes provide key advantages such as durability, chemical resistance, cost-effectiveness, and recyclability. These benefits make them a reliable solution for packaging and storage across various industries, including food, chemicals, and industrial applications. With sustainability being a growing priority, HDPE boxes are essential in meeting eco-friendly packaging demands.ZhangJiaGangFenghui logistics equipment Co., Ltd. offers high-quality HDPE boxes that meet industry standards, providing businesses with efficient, durable, and sustainable packaging solutions.

A: An HDPE box is a container made from High-Density Polyethylene, a durable plastic known for its strength, chemical resistance, and recyclability. It is widely used for packaging, storage, and transportation.

A: HDPE boxes offer durability, resistance to chemicals, cost-effectiveness, and recyclability. They are ideal for industries requiring strong, long-lasting containers.

A: HDPE boxes are manufactured through processes like injection molding and blow molding, where the plastic is shaped into containers under high pressure.

A: Yes, HDPE boxes are recyclable and contribute to sustainability by reducing waste and supporting the circular economy.

A: HDPE boxes are stronger, more chemical-resistant, and more cost-effective than alternatives like glass or metal, making them ideal for heavy-duty and industrial applications.