Views: 0 Author: Site Editor Publish Time: 2025-09-02 Origin: Site

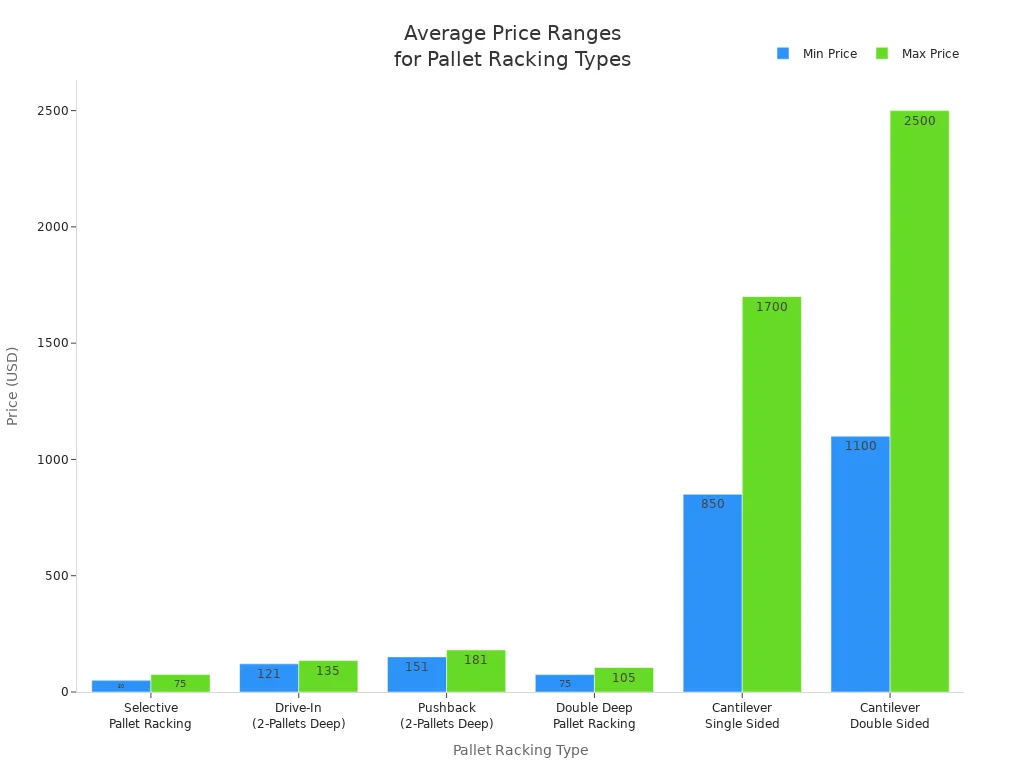

You may ask, "How much does pallet racking cost?" The price changes based on rack type, size, and what you need for your project. Here is a quick look at average prices from recent market data:

Type of Pallet Racking | Average Price Range |

|---|---|

Selective Pallet Racking | $50.00 – $75.00 per pallet position |

Drive-In Pallet Racking (2-Pallets Deep) | $121.00 – $135.00 per pallet position |

Pushback Pallet Racking (2-Pallets Deep) | $151.00 – $181.00 per pallet position |

Double Deep Pallet Racking | $75.00 – $105.00 per pallet position |

Cantilever Racking – Single Sided | $100.00 – $350.00 per bay |

Cantilever Racking – Double Sided | $200.00 – $550.00 per bay |

Prices can go up or down because of steel costs, rack material, and how much weight the rack can hold. You can also pick custom design and rapid prototyping services to fit your exact pallet rack needs.

Pallet racking prices change based on type, size, and material. Selective racks cost from $50 to $200 for each pallet spot. Cantilever racks cost between $850 and $2,500 for each bay.

Think about load capacity and height when picking racks. Racks that hold more or are taller usually cost more. This is because they need stronger materials and special design.

Custom features can make your pallet racking system better. But these features may add 10% to 30% to your total price. Custom design makes sure the racks fit your warehouse needs.

Installation and freight costs are important to remember. Installation costs from $2 to $5 for each square foot. Freight costs depend on how heavy and far the racks must go.

Always plan for safety accessories in your budget. Things like wire decking and column guards make racks safer. They also help protect your investment.

If you look at pallet racking systems, you will see each type costs differently and has its own features. You must pick the best system for your warehouse, your products, and your budget. Here is a simple list of the main types and what they cost.

Selective racks let you reach every pallet directly. You can use them in many kinds of warehouses. The usual price for selective racks is $50 to $200 for each pallet spot.

Some things change the price:

Custom racks fit your space and products, but they can cost more.

The material you pick, like steel or aluminum, changes the price. Stronger materials last longer.

New and eco-friendly materials are getting popular. These can cost more but help save energy and cut down on waste.

Zhangjiagang Fenghui logistics equipment Co., Ltd. sells metal pallet racks. They offer free design, easy stacking, and recycling.

Type of Rack | Cost Range (per pallet position) |

|---|---|

Selective Pallet Racks | $50 – $200 |

Drive-in racks let you put pallets deep inside the rack. You drive a forklift into the rack to get or place pallets. The price for drive-in racks is usually $200 to $500 for each pallet spot.

Here are some things to think about:

Custom racks match your warehouse and product size.

If you need racks for cold places or earthquake zones, you may pay more for special materials.

Storing more pallets can wear out racks faster, which can raise costs.

Zhangjiagang Fenghui logistics equipment Co., Ltd. can make drive-in racks for cars and factories. Their racks are strong, easy to stack, and nest.

Pushback racks help you use space better. You put pallets on both sides of an aisle and push back the last pallet to add more.

The price changes with depth:

Configuration | Price Range (per pallet position) |

|---|---|

2-Pallets Deep | $151.00 – $181.00 |

3-Pallets Deep | $176.00 – $216.00 |

4-Pallets Deep | $210.00 – $250.00 |

5-Pallets Deep | $243.00 – $273.00 |

You can pick special sizes, colors, or ways to handle pallets. Strong materials like alloy steel cost more but last longer. Zhangjiagang Fenghui logistics equipment Co., Ltd. has pushback racks with free design and long-lasting strength.

Cantilever racks are good for long or big items like pipes or wood. You get easy access and flexible storage.

Material strength and green features change the price. Strong steel makes racks last up to 40% longer. Racks made from recycled stuff lower your carbon footprint by 15%.

Type | Details |

|---|---|

Single Sided | $850.00 – $1,700.00 per bay |

Double Sided | $1,100.00 – $2,500.00 per bay |

Zhangjiagang Fenghui logistics equipment Co., Ltd. has cantilever racks with lots of choices. You can ask them for a price that fits your needs.

When you plan your warehouse storage, you need to know what affects the price of a pallet rack system. Several key factors can change new pallet racking costs. Understanding these will help you make smart choices and avoid surprises.

The size and load capacity of your racks play a big role in cost. Larger racks need more materials and stronger engineering. If you need racks that hold more weight, you will pay more because of the extra strength and design work. Most warehouses use racks that hold up to 5 tons, but some need racks for 5-15 tons or even more. As the load capacity goes up, new pallet racking costs rise.

Tip: Always check your warehouse’s ceiling height and forklift reach. Taller racks may cost more due to safety rules and building limits.

Factor | Description |

|---|---|

Load Capacity | Heavier loads require stronger, more expensive materials and design. |

Height | Taller racks may cost more due to safety and building requirements. |

Type of Racking | The right type for your needs affects both price and performance. |

The material you choose changes the price. Steel racks are the most common because they last a long time and hold heavy loads. If you pick wood or aluminum, you might save money, but these do not last as long. The finish also matters. Galvanized racks resist rust and last longer, but they cost more. Powder-coated and painted finishes offer protection at a lower price.

Steel: Most durable and common, higher cost.

Aluminum or wood: Cheaper, but less durable.

Galvanized finish: Best for long life, higher price.

Powder-coated or painted: Good protection, lower price.

You can save money by buying used racks. Used racks usually cost 30-50% less than new ones. The price depends on their condition and features. If you want the latest safety features or custom sizes, new pallet racking costs will be higher.

Custom features can make your storage fit your exact needs. These might include special sizes, colors, or extra safety parts. Customization can add 10% to 30% to your total cost. When you work with a supplier that offers custom design and prototyping, you get racks that match your needs and avoid costly changes later. Prototyping helps spot design issues early, saving money in the long run.

Custom design avoids over- or under-building.

Prototyping predicts load and service life.

You get racks that fit your real-world needs.

When you plan a pallet racking project, you must think about more than rack prices. The total cost has installation, freight, accessories, and getting quotes. Here is how you can figure out your whole project cost:

Installation costs change with the racking system type and project size. Some racks need more work and time. VNA systems and pallet shuttle systems are harder to set up. They cost more to install because they are complex. Most installation costs are $2 to $5 for each square foot.

Racking System Type | Cost per Pallet Position | Installation Cost per Rack |

|---|---|---|

VNA Systems | $100 to $150 | $350 to $500 |

Pallet Shuttle Systems | $200 to $300 | $500 to $800 |

Note: Labor costs change by where you live and how skilled the team is.

Freight and delivery charges are a big part of your cost. The weight of your racks, how far they travel, and the delivery type all matter. If your racks weigh less than 40,000 lbs, you might only need one truck. This makes freight costs easier to guess. Always ask your supplier for a shipping quote.

You should add accessory and safety equipment costs to your budget. Things like wire decking, column guards, and rack protectors keep your warehouse safe. These extras raise your cost but protect your racks and help safety.

Wire decking

Upright protectors

Row spacers

Safety bars

To get a good quote for your pallet racking project, do these steps:

Find out what kind and quality of pallets you use.

Write down your inventory details and storage needs.

Explain how you move your inventory.

Share your warehouse layout and environment.

Work with a rack expert to check your needs and make a plan.

Tip: Always talk to suppliers like Zhangjiagang Fenghui logistics equipment Co., Ltd. for a quote that fits your project.

By adding installation, freight, accessories, and a good quote process, you can make a clear budget for your new pallet racking system.

When you pick a warehouse storage system, you want more than strong racks. You also need services that help you save money and finish on time. These services can make your project better and easier. Zhangjiagang Fenghui logistics equipment Co., Ltd. offers custom design and rapid prototyping. These services help your pallet rack system fit your needs.

Custom design means you get racks that fit your warehouse and products. You work with experts who know about storage and your business. They use special tools to make layouts that use space well and follow safety rules. You can choose the materials, sizes, and colors you like best.

Here is what you get with custom design:

Strength | Description |

|---|---|

Industry Expertise | Experts give advice about pallet rack systems and materials. |

Material Sourcing | You can pick from many materials, even eco-friendly ones. |

Customization Options | You can ask for special features for your needs. |

Compliance | Your racks will meet all safety and industry rules. |

Custom design helps you use space well and avoid mistakes. You can see your layout before it is built, so you know it will work.

Prototyping gives you a sample rack before making all of them. You can test it in your warehouse to see how it works. If you want changes, you can make them fast. This saves you time and money.

Benefits of prototyping include:

You get samples quickly, sometimes in just days.

You can change designs easily with real-time feedback.

You can test the rack in real warehouse conditions.

Quality control checks make sure your rack is good.

Zhangjiagang Fenghui logistics equipment Co., Ltd. uses advanced machines and digital tools for prototyping. You get good results and an easy move to full production.

If you want a pallet rack system that fits your needs and budget, contact Zhangjiagang Fenghui logistics equipment Co., Ltd. for a custom solution. Their team will help you from design to installation.

You can check the table to see price estimates for pallet racks. These numbers help you figure out your budget:

Pallet Rack Type | Price Range (per pallet position) |

|---|---|

Single-Deep Pallet Racks | $55 to $200 |

Double-Deep Pallet Racks | $85 to $300 |

Your total cost depends on many things. These include how much weight the rack holds, how complex the system is, which dealer you pick, safety rules, steel prices, and the brand’s reputation.

Don’t forget to add installation, permits, and accessories to your budget. Custom design and prototyping services make sure your racks fit well and give you good value. If you want a quote made just for you, ask Zhangjiagang Fenghui logistics equipment Co., Ltd. for expert help.

First, check your product size and weight. Think about how often you need to reach your products. Look at your warehouse layout and ceiling height. Custom design services from Zhangjiagang Fenghui logistics equipment Co., Ltd. can help you find the best fit.

You can set up simple racks if you follow safety rules. For bigger or more complex racks, hire professionals. This makes sure your pallet racking is safe and works well.

Most pallet racking lasts between 15 and 20 years. You need to check racks often and fix damage fast. Using strong materials from trusted suppliers helps racks last longer.

Contact Zhangjiagang Fenghui logistics equipment Co., Ltd. directly. Tell them your warehouse size, product details, and storage needs. Their team will give you a custom quote and expert advice.

Use wire decking, column guards, and rack protectors. These accessories help stop accidents and keep your warehouse safe. Ask your supplier for tips based on your storage system.